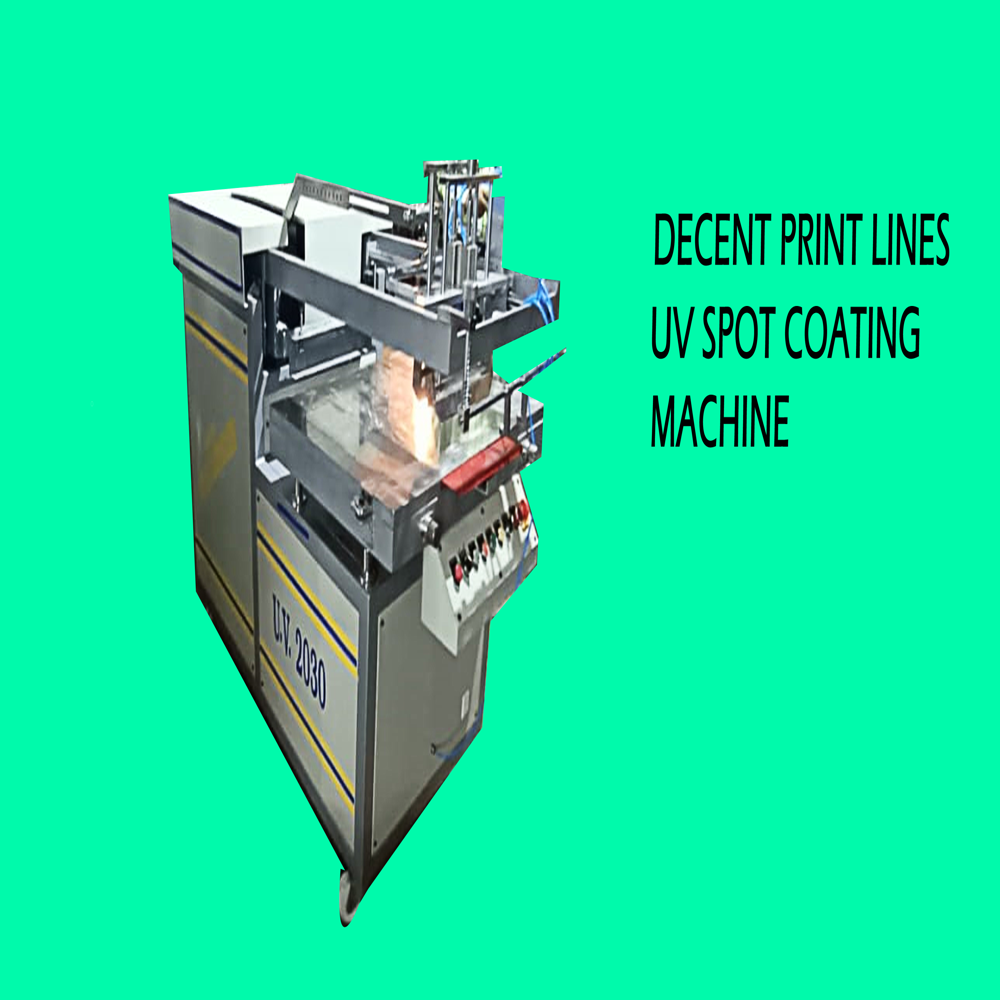

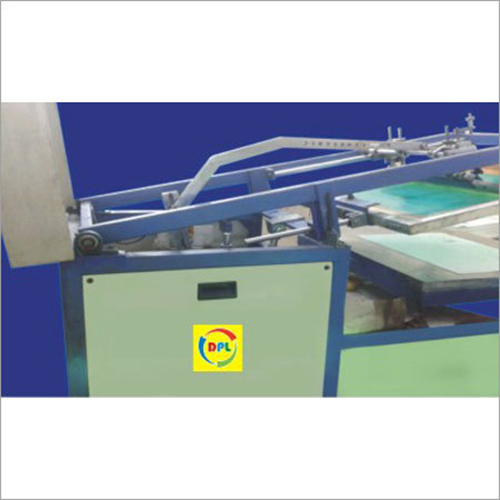

UV Spot Coating Machine

UV Spot Coating Machine Specification

- Type

- Screen Printing Machine

- Material

- M S

- Capacity

- 1500 Pcs/hr

- Printing Speed

- 1500 PPM

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Plate Type

- Screen Printer

- Print Direction

- Bi-Directional

- Ink Type

- UV Curing Ink

- Color Management

- Other

- Control System

- Human Machine Interface

- Power

- 5 Horsepower (HP)

- Width

- 5 Foot (ft)

- Weight (kg)

- 1100 Kilograms (kg)

- Dimension (L*W*H)

- 14 Foot (ft)

- Warranty

- 1 year

UV Spot Coating Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Supply Ability

- 4 Units Per Month

- Delivery Time

- 10 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

About UV Spot Coating Machine

A UV spot coating machine is a specialized finishing machine that applies a clear highgloss or sometimes matte UVcurable varnish to specific predefined areas of a printed sheet The coating is then instantly cured by ultraviolet light This process creates a striking contrast between the coated glossytextured and uncoated usually matte or semigloss areas enhancing visual appeal and tactile experience Its widely used for premium printing packaging business cards brochures and book covers to make logos images or text pop

In Faridabad Haryana India you can find manufacturers and suppliers of UV spot coating machines such as Decent Print Lines P3 Machinery SK Ensure Machinery Private Limited Pearl Print Pack Taniya Machinery Private Limited Dashmesh Print Line Lolita Manufacturing Works and Kamal Sales Corporation

Heres a detailed breakdown of specifications for a UV spot coating machine

I Core Functionality Technology

Application Method

Screen Printing Based This is the most common method for spot UV A screen with an open area corresponding to the spot design is used The UV varnish is pushed through this open area onto the substrate

OffsetFlexo Plate Based Some highend machines use a printing plate similar to offset or flexo to transfer the spot UV varnish These are often integrated with offset presses or operate as highspeed standalone units

Digital Spot UV DVS Digital Varnish System Emerging technology that uses inkjet print heads to digitally print the UV varnish Offers high versatility variable data capabilities and no need for platesscreens but often at a higher cost for the machine

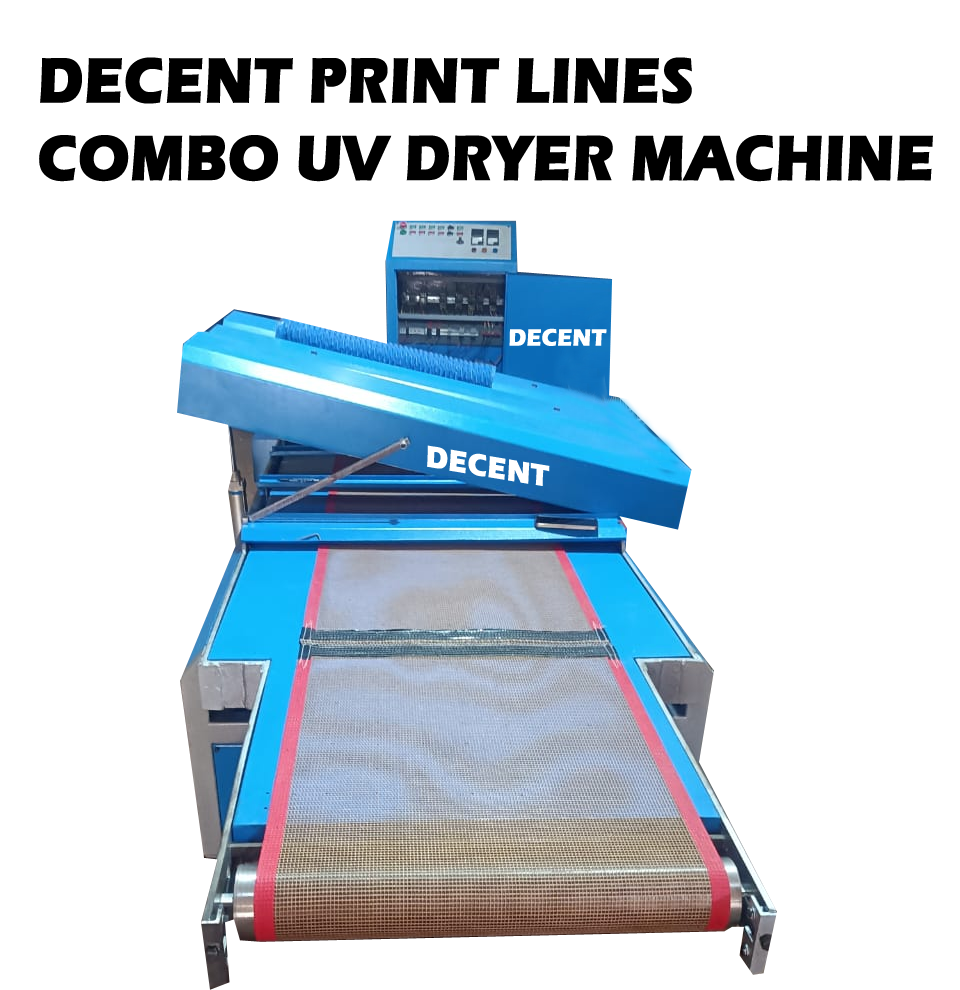

UV Curing Technology

UV Lamps Highintensity UV lamps usually mercury vapor lamps are used to instantly cure the applied varnish

LED UV Emerging Uses LED lights for curing Offers lower energy consumption longer lamp life and less heat generation but UV LED varnishes can be more expensive

Contrast Effect

High Gloss Spot UV Most common providing a shiny reflective finish

Matte Spot UV Less common but can create a subtle elegant contrast

Textured3DRaised Spot UV DripOff Achieved by applying a specific varnish often a matte one in combination with the spot UV creating a tactile raised effect

II Key Specifications

Automation Grade

ManualSemiAutomatic Operator manually feeds sheets into the machine which then automatically applies the spot coating and cures it Output is also often manually stacked Common for smaller or midrange machines in India

Automatic Features automatic feeding eg suction feeder precise registration coating application curing and automatic deliverystacking Designed for high volume

Maximum and Minimum Sheet Size

This is critical as it defines the working envelope of the machine

Max Sheet Size Commonly ranges from 18 x 24 457 x 610 mm to 30 x 40 762 x 1016 mm or larger for industrial models eg 40 x 55

Max PrintingCoating Area Slightly smaller than the max sheet size due to gripper margins For example a machine handling 18x24 sheets might have a max coating area of 15x22 381 x 559 mm or 456 x 610 mm

Min Sheet Size Can be as small as 85 x 11 216 x 279 mm or even smaller for specialized machines eg 125 x 180 mm

Material Thickness Compatibility GSM

PaperBoard Typically handles a range from 80 GSM or 200 GSM in some cases up to 450 GSM Some robust machines can handle up to 600 GSM or thicker board

Can also be used on some plastic sheets PVC PET

PrintingCoating Speed Impressions Per Hour IPH

SemiAutomatic Often ranges from 800 to 1500 IPH Some models like those from P3 Machinery list up to 1300 IPH or 1000 sheets per hour

Automatic Can achieve much higher speeds from 2000 to 5000 IPH or even 8000 sheets per hour for highspeed industrial models

ScreenPlateHead System depending on technology

For Screen Printing Based Machines

Max Screen Frame Size The largest screen frame that can be mounted eg 24 x 30 or 30 x 40

MicroRegistration Highly precise XY axis and rotational adjustments for aligning the screen with the preprinted image

Squeegee and Flood Bar Adjustable pressure angle and stroke for optimal varnish application

For Digital Spot UV

Inkjet Print Heads Specifications on the type and number of print heads

UV Lamp Specifications

Number of Lamps Typically 1 to 2 UV lamps for curing

Lamp Power Measured in kW or Winch eg 56 kW x 2 lamps or 200500 Winch Higher power ensures faster and more complete curing

Cooling System Integrated blowers and exhaust systems to dissipate heat

Lamp Life Manufacturerspecified expected lifespan

Safety Features UV shielding automatic lamp shutoff when covers are open or conveyor stops

Feeder System

Manual Feeding Simplest operator places each sheet

Automatic Suction Feeder Uses vacuum suckers to pick up and feed sheets one by one ensuring consistent feeding

Pile Height Max stack height the feeder can handle

Delivery System

Conveyor Often a mesh belt or roller conveyor to transport sheets through the UV curing unit

Receding StackerAutomatic Stacker Neatly collects coated sheets

Jogger To align sheets on delivery

Power Requirements

Voltage Commonly 220V single phase for smaller models or 380V415V440V three phase for larger more automated machines

Total Power Consumption kWHP Varies widely from 15 kW to 16 kW or more depending on the machines size automation and UV lamp power

Machine Dimensions and Weight

Crucial for factory layout Spot UV machines can be quite compact or fairly large

Weight can range from a few hundred kg eg 300400 kg for semiautomatic to over 1500 kg for automatic models

III Additional Features

Precise Registration System Essential for accurate spot UV placement Features like front lay side lay and finetuning adjustments for precise alignment with preprinted images

Vacuum Table To hold the sheet flat and stable during the coating process

InkVarnish Circulation System Ensures consistent supply of UV varnish to the application unit

Automatic Cleaning System For rollers or screen simplifying maintenance

Centralized Lubrication System For smooth operation and reduced wear

Touch Screen Control Panel For userfriendly operation setting parameters and monitoring

Emergency Stop Button For operator safety

Versatility Some machines can do both full flood UV coating and spot UV coating

OnlineOffline Capability Can be a standalone offline unit or integrated with a printing press for online finishing

When looking for a UV spot coating machine in Faridabad its highly recommended to contact local manufacturers directly such as those mentioned earlier They can provide specific model specifications pricing which can vary widely from around 125 Lakh to 20 Lakhs or more depending on features and automation and demonstrations based on your exact production needs

FAQs of UV Spot Coating Machine:

Q: What type of ink does the UV Spot Coating Machine use?

A: The UV Spot Coating Machine uses UV Curing Ink.Q: What is the capacity of the UV Spot Coating Machine?

A: The machine has a capacity of 1500 pieces per hour.Q: Is the UV Spot Coating Machine fully automatic?

A: No, the machine is semi-automatic.Q: What is the weight of the UV Spot Coating Machine?

A: The machine weighs 1100 kilograms (kg).Q: What is the warranty period for the UV Spot Coating Machine?

A: The machine comes with a 1-year warranty.Q: What type of printer plate is used in this machine?

A: The machine uses a screen printer plate.Q: What is the dimension of the UV Spot Coating Machine?

A: The dimensions of the machine are 14 feet in length.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

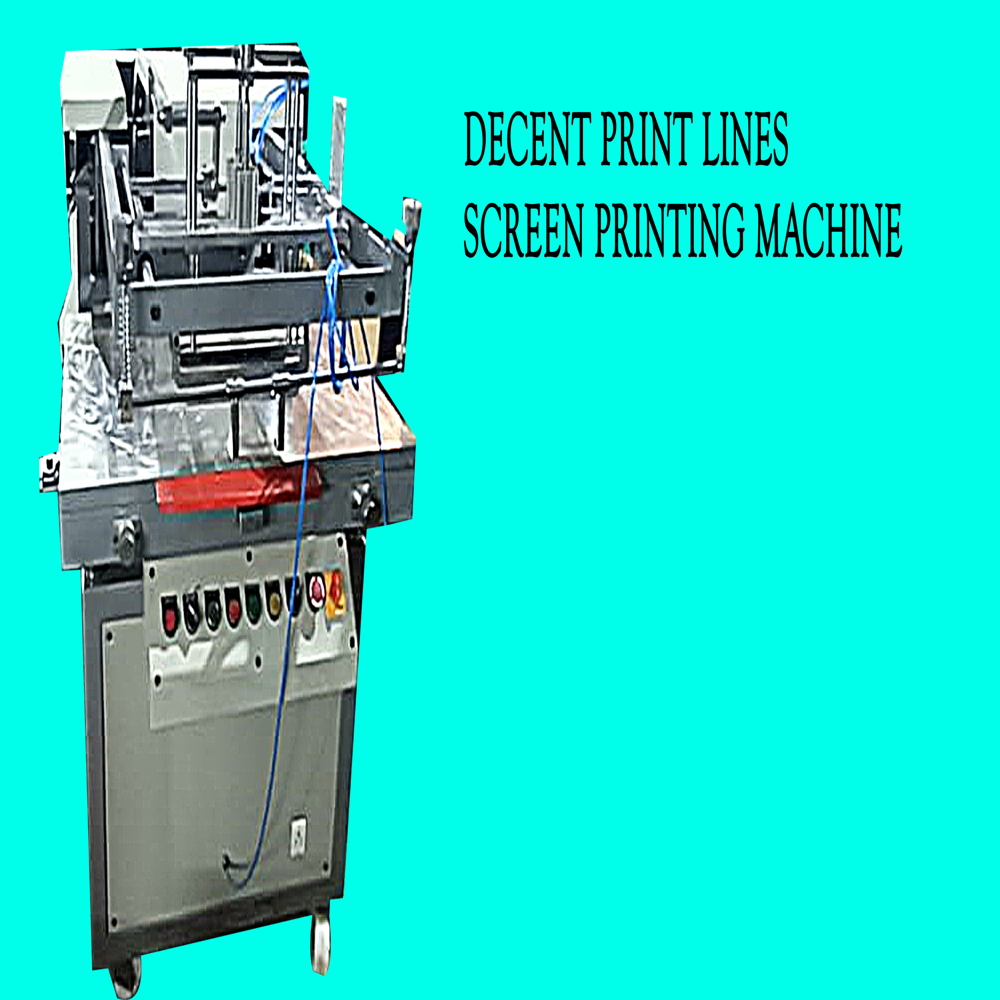

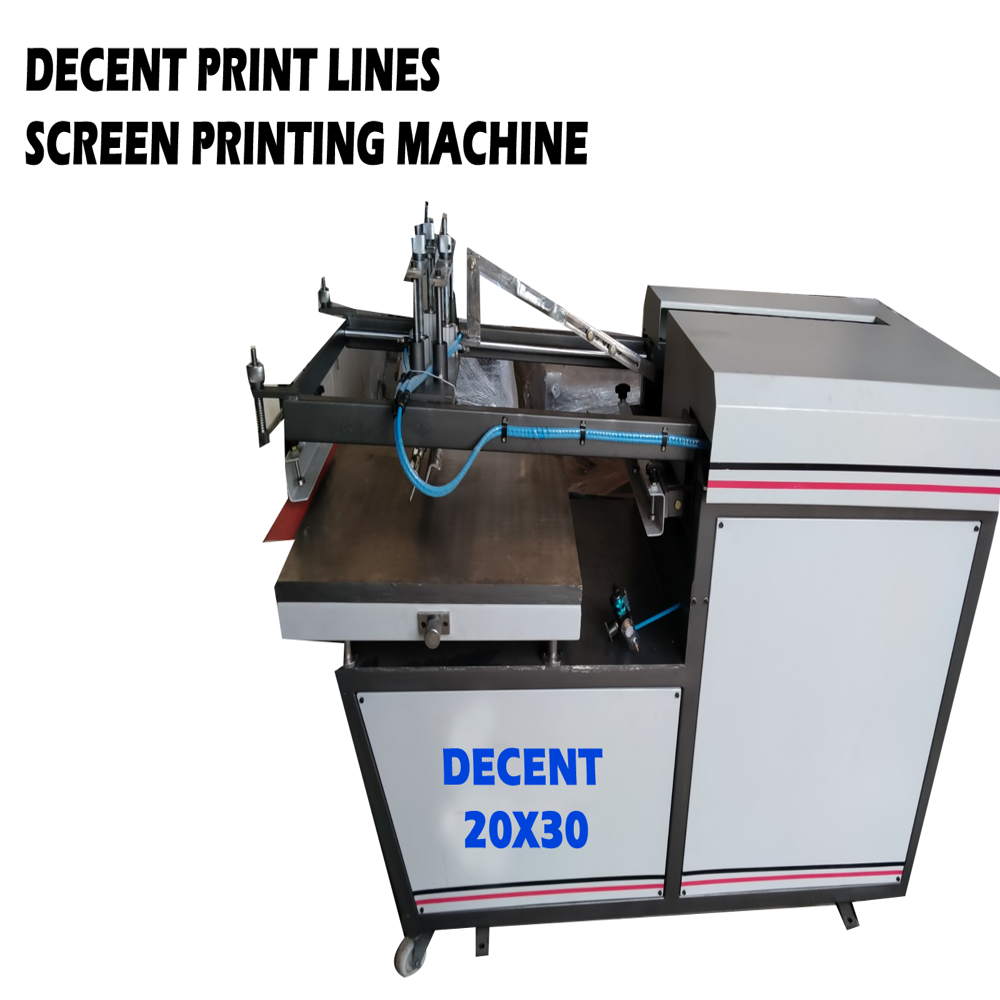

More Products in Flat Screen Printing Category

Flat Screen Printing Machine

Price 250000 INR / Set

Minimum Order Quantity : 1 Piece

Color Management : Other

Computerized : No

Warranty : 1 year

Print Direction : Other

Screen Printing Machine

Price 250000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Color Management : Other

Computerized : Yes

Warranty : Placeholder Value

Print Direction : Other

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese