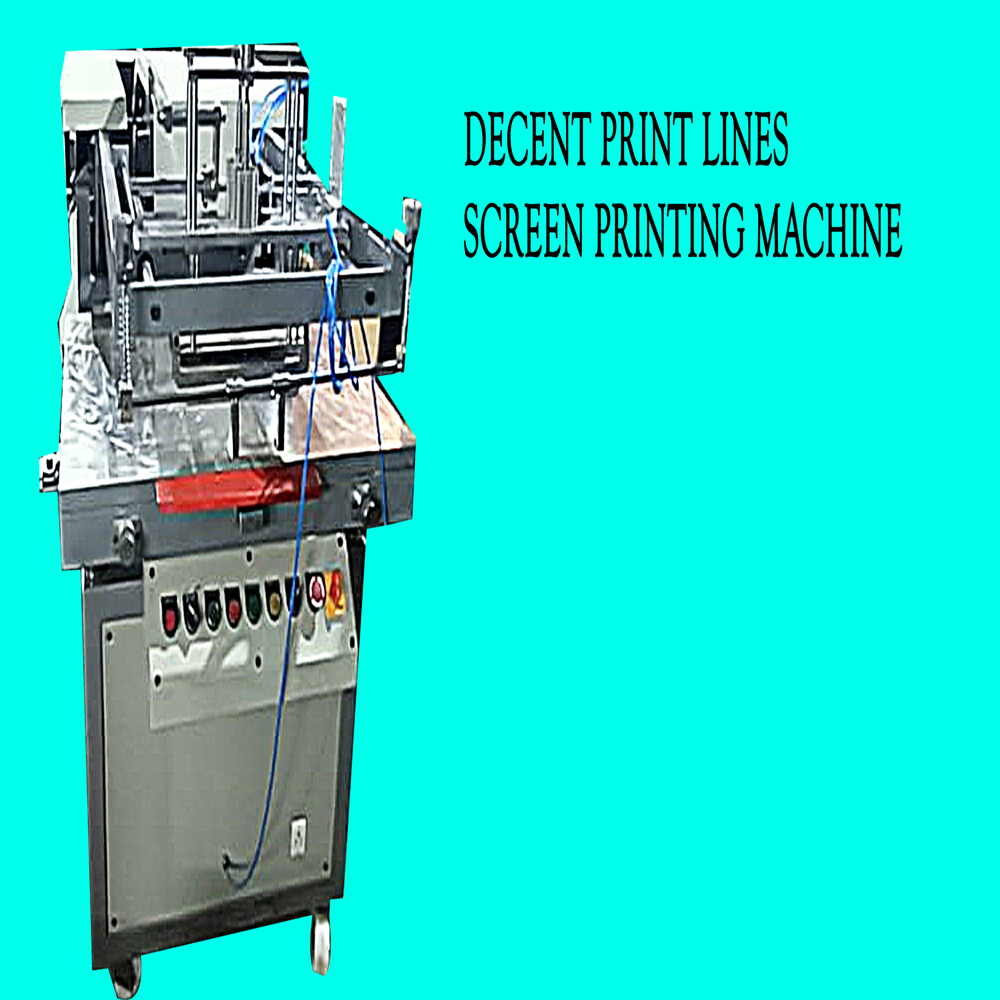

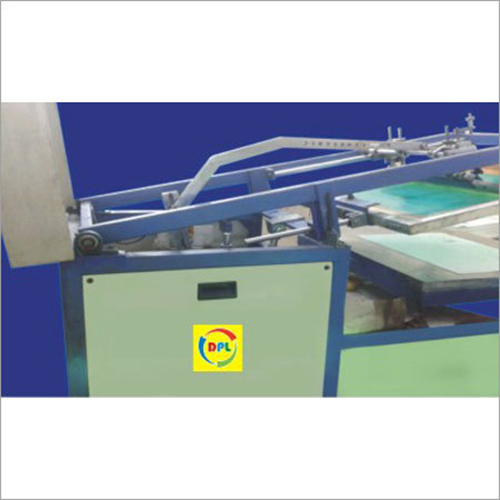

Screen Printing Machine

Screen Printing Machine Specification

- Type

- Offset Printing Machine

- Material

- Plastic

- Computerized

- Yes

- Print Direction

- Other

- Color Management

- Other

- Size

- Placeholder Value

- Warranty

- Placeholder Value

Screen Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Supply Ability

- 6 Units Per Month

- Delivery Time

- 5 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Eastern Europe, Western Europe, Africa

About Screen Printing Machine

Screen printing is a versatile printing technique that involves pushing ink through a mesh screen onto a substrate. It's known for producing vibrant colors, thick ink deposits, and durability. Screen printing machines come in various forms, from simple manual setups to highly automated industrial systems, catering to a wide range of applications and production volumes.Given that you are in Faridabad, Haryana, India, you'll find numerous manufacturers and suppliers like Decent Print Lines, P3 Machines, SK Ensure Machinery Private Limited, Kamal Sales Corporation, and others offering a variety of screen printing machines.

Here's a breakdown of common specifications for screen printing machines:

I. Types of Screen Printing Machines:

-

Manual Screen Printing Machines:

-

Clamshell: The screen lifts straight up like a clamshell. Simple, compact, and affordable, ideal for beginners, hobbyists, or small-scale operations.

-

Hinged/Swing-away: The screen lifts and swings away, providing better access to the platen.

-

Rotary (Carousel) Presses: Multiple platens and print heads arranged in a circle, allowing for multi-color printing by rotating stations. Common for T-shirt printing.

-

-

Semi-Automatic Screen Printing Machines:

-

Typically feature an automatic print head movement (squeegee and flood bar) but require manual loading and unloading of the substrate.

-

Often include vacuum beds for flat materials to hold them in place.

-

Suitable for medium production volumes and consistent quality.

-

-

Automatic Screen Printing Machines:

-

Fully automated processes, including automatic loading, printing, curing, and unloading.

-

High production speeds and consistent quality, ideal for large-scale industrial operations.

-

Can be Flatbed, Cylinder, or Rotary (for continuous web materials).

-

Specialized automatic machines exist for specific items like bottles, buckets, pens, or circuit boards.

-

II. Key Specifications:

-

Automation Grade:

-

Manual: Operator-driven for all movements.

-

Semi-Automatic: Automated printing stroke, manual loading/unloading.

-

Automatic: Full automation from feeding to delivery.

-

-

Object/Material to be Printed:

-

Flat Surface: Paper, cardboard, plastic sheets, sunpack boards, wedding cards, banners, metal sheets, PCBs, stickers, leather, ceramic tiles, glass, etc. (Flatbed machines).

-

Fabric/Textile: T-shirts, garments, non-woven bags, jute bags, cotton bags, ribbons, flags, towels (often uses specialized textile presses or flatbed).

-

Cylindrical/Round Objects: Bottles, cups, mugs, buckets, pens, tubes, syringes (requires specialized rotary screen printers).

-

Irregular Shapes: Some machines can handle slightly irregular or pre-formed objects.

-

-

Maximum and Minimum Print Area/Sheet Size:

-

This is crucial as it determines the largest and smallest item/design the machine can handle.

-

Print Area: Common sizes range from 15"x20" to 30"x40" for flatbed machines. Larger industrial machines can go up to 40"x72" or even bigger.

-

Max Sheet/Substrate Size: Typically slightly larger than the max print area.

-

Min Sheet Size: Can be quite small for specialized machines.

-

-

Maximum Screen Frame Size:

-

The largest screen frame that can be mounted on the machine. This dictates the maximum print area.

-

Common sizes: 20"x24", 24"x32", 30"x40", up to 36"x48" or more.

-

-

Printing Speed (Impressions Per Hour - IPH or Pieces Per Hour):

-

Manual: 100-300 IPH (highly dependent on operator skill).

-

Semi-Automatic: 800-1500 IPH (e.g., P3 Machines list 1200-1500 pcs/hr for some models).

-

Automatic: 1200-5000+ IPH, with some specialized machines reaching much higher speeds (e.g., 4300 parts per hour for cylindrical printing).

-

-

Number of Colors:

-

Single Color: Most basic machines.

-

Multi-Color: For printing designs with multiple colors. This can be achieved either by printing one color at a time and manually changing screens (manual rotary presses) or with multiple print heads (automatic multi-color presses).

-

Note: CMYK process printing is possible with screen printing, but it requires precise registration and often specialized equipment.

-

-

Power Requirements:

-

Voltage: 220V (single phase) for smaller/manual/semi-automatic machines; 380V/415V (three phase) for larger automatic industrial machines.

-

Power Consumption (kW or HP): Ranges from 0.5 HP (manual with vacuum) to 5 HP or more for main motors, with total power consumption increasing significantly for automatic machines with conveyors, UV curing, etc. (e.g., 2.25 kW to 3 kW or up to 105 kW for large textile screen printing lines).

-

-

Air Compressor Requirement:

-

Many semi-automatic and automatic screen printing machines are pneumatic and require an external air compressor for squeegee/flood bar movement, screen lifting, vacuum bed operation, etc.

-

Air Pressure: Typically 6 Bar (85 psi).

-

Compressor Power: 1 HP to 6 HP, depending on the machine size and features.

-

-

Drying/Curing System (often separate or integrated):

-

Flash Curer/Dryer: For textile printing, to partially cure ink between colors.

-

Conveyor Dryer: For continuous drying of prints (hot air, IR, or UV).

-

UV Curing: For UV inks, which cure instantly under UV light (common for non-absorbent substrates like plastic, glass, metal).

-

III. Mechanical & Operational Features:

-

Vacuum Bed/Table: Essential for holding flat substrates firmly in place during printing, ensuring sharp, clean prints. Often made of stainless steel.

-

Micro-Registration System: Crucial for multi-color printing, allowing for fine adjustments (X, Y, and rotational axes) of the screen frame to achieve perfect alignment.

-

Squeegee and Flood Bar System:

-

Adjustable Squeegee Angle and Pressure: To control ink deposit and print quality.

-

Print Stroke and Speed Adjustment: To optimize for different inks and substrates.

-

Pneumatic or Motorized Movement: For consistent and automated printing.

-

-

Screen Frame Clamping System: Robust clamps to hold the screen securely.

-

Adjustable Worktable: Allows for precise positioning of the substrate.

-

Safety Features: Emergency stop buttons, safety guards, interlocks.

-

Durability: Machines are typically constructed from mild steel (MS), stainless steel (SS), or aluminum alloy.

-

User Interface: Control panel, sometimes with a digital display or touchscreen, for setting parameters.

IV. Specialized Screen Printing Machines:

-

Textile Screen Printing Machines: Often have specific platen designs (e.g., for T-shirts), flash curers, and can be multi-color manual or automatic carousels.

-

Rotary Screen Printing Machines (Roll-to-Roll): For continuous printing on flexible roll materials like fabrics, films, labels.

-

Cylindrical Screen Printing Machines: Designed with specialized fixtures and movements to print on round objects.

-

Semi-Automatic Flat Screen Printing Machines: A very popular type in India for general purpose flat printing.

-

Large Format Screen Printing Machines: For printing on very large sheets like banners, posters, or architectural glass.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Flat Screen Printing Category

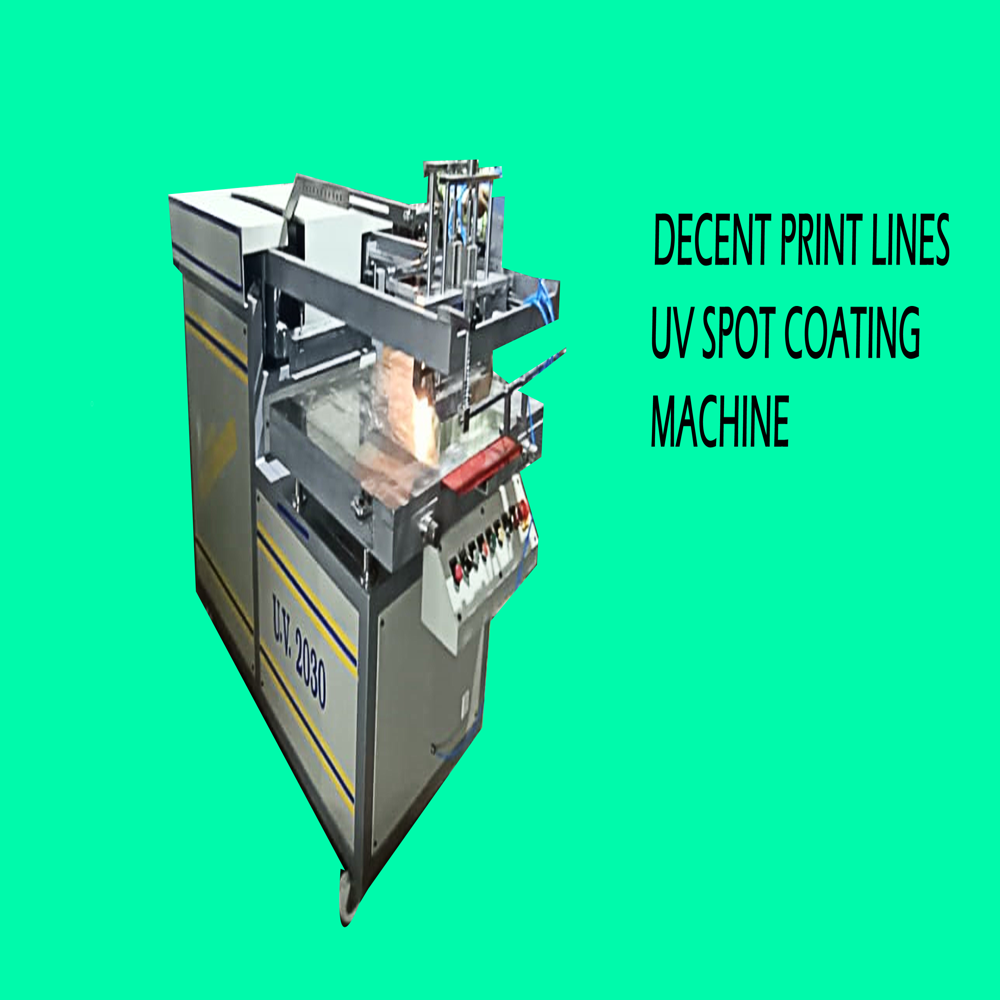

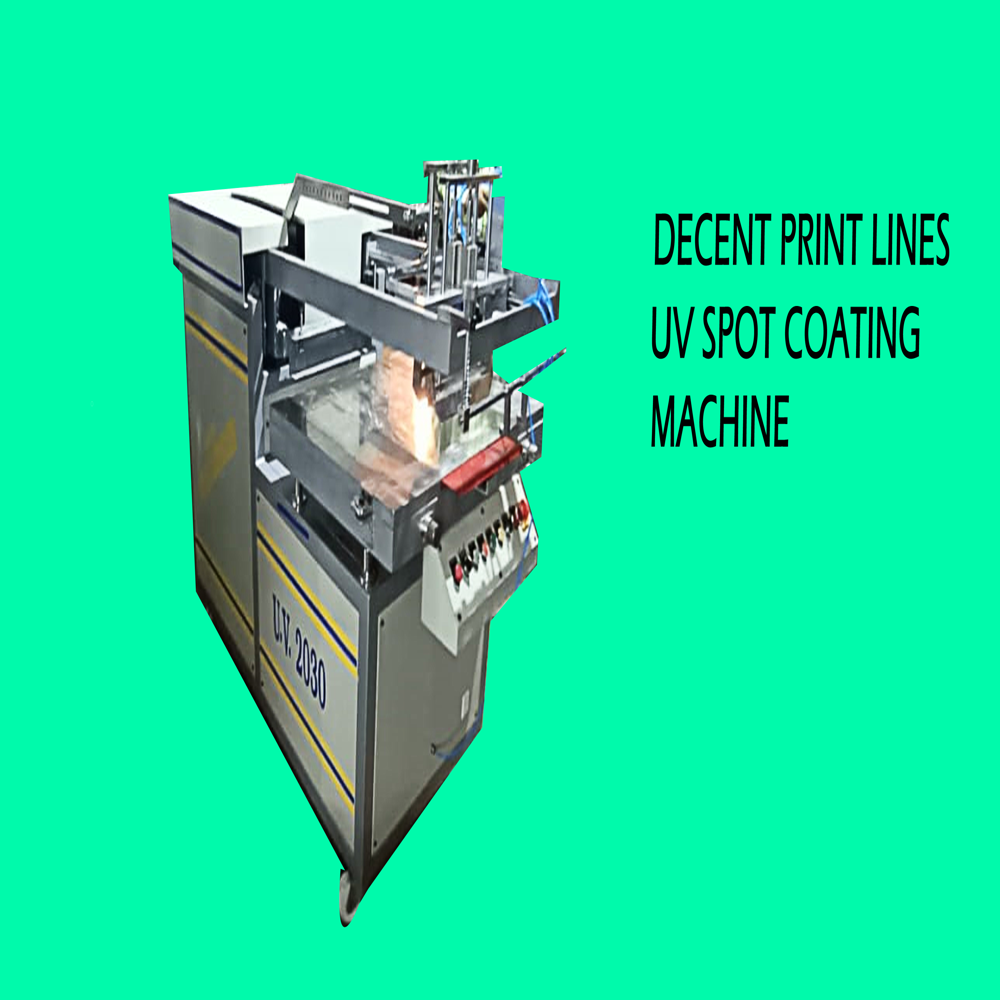

UV Spot Coating Machine

Price 500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Print Direction : BiDirectional

Plate Type : Screen Printer

Automatic Grade : SemiAutomatic

Ink Type : UV Curing Ink

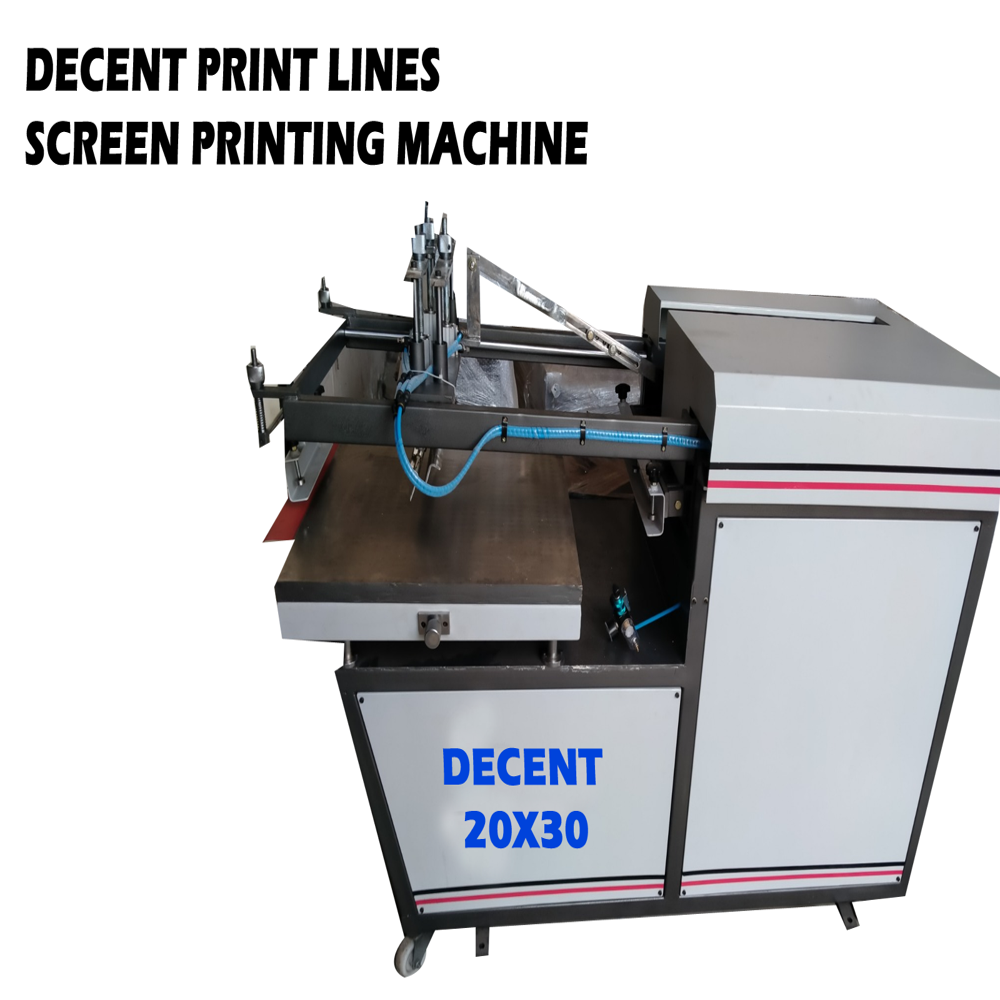

Flat Screen Printing Machine

Price 250000 INR / Set

Minimum Order Quantity : 1 Piece

Print Direction : Other

Plate Type : Screen Printer

Automatic Grade : SemiAutomatic

Ink Type : UV Curing Ink

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese