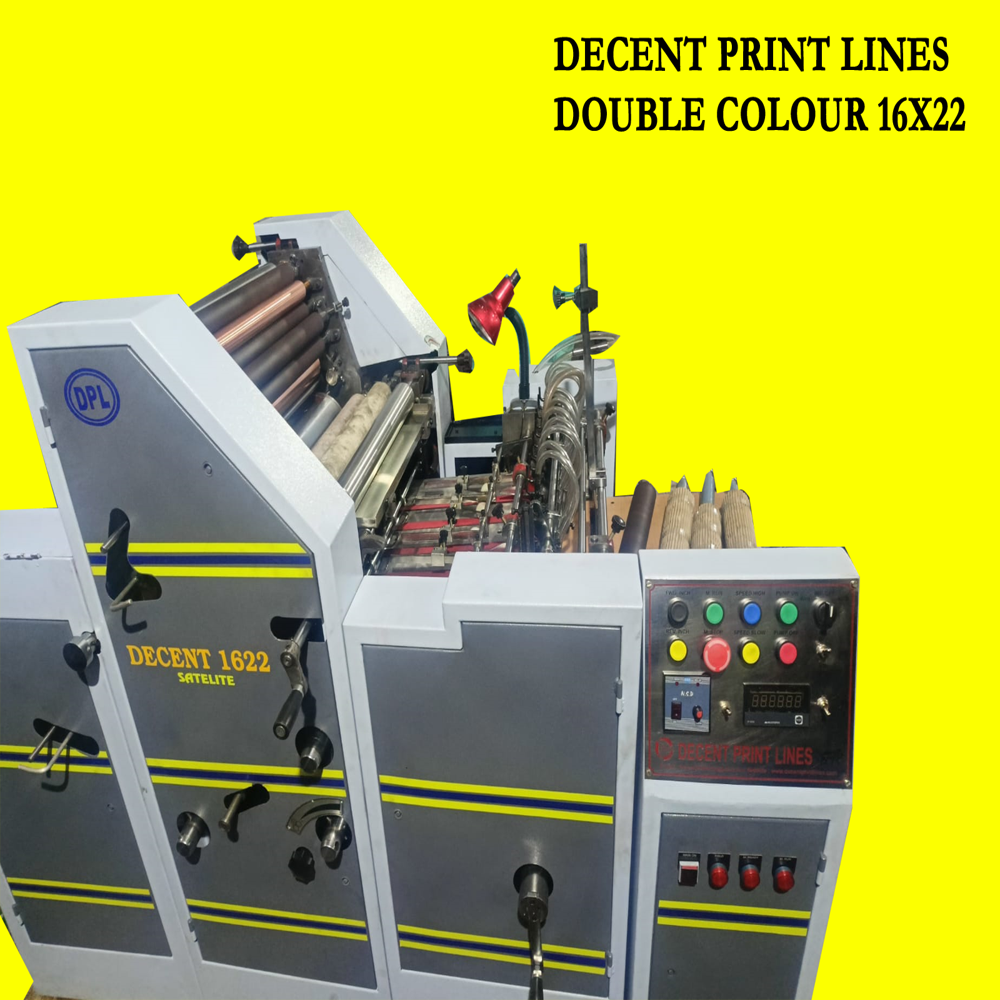

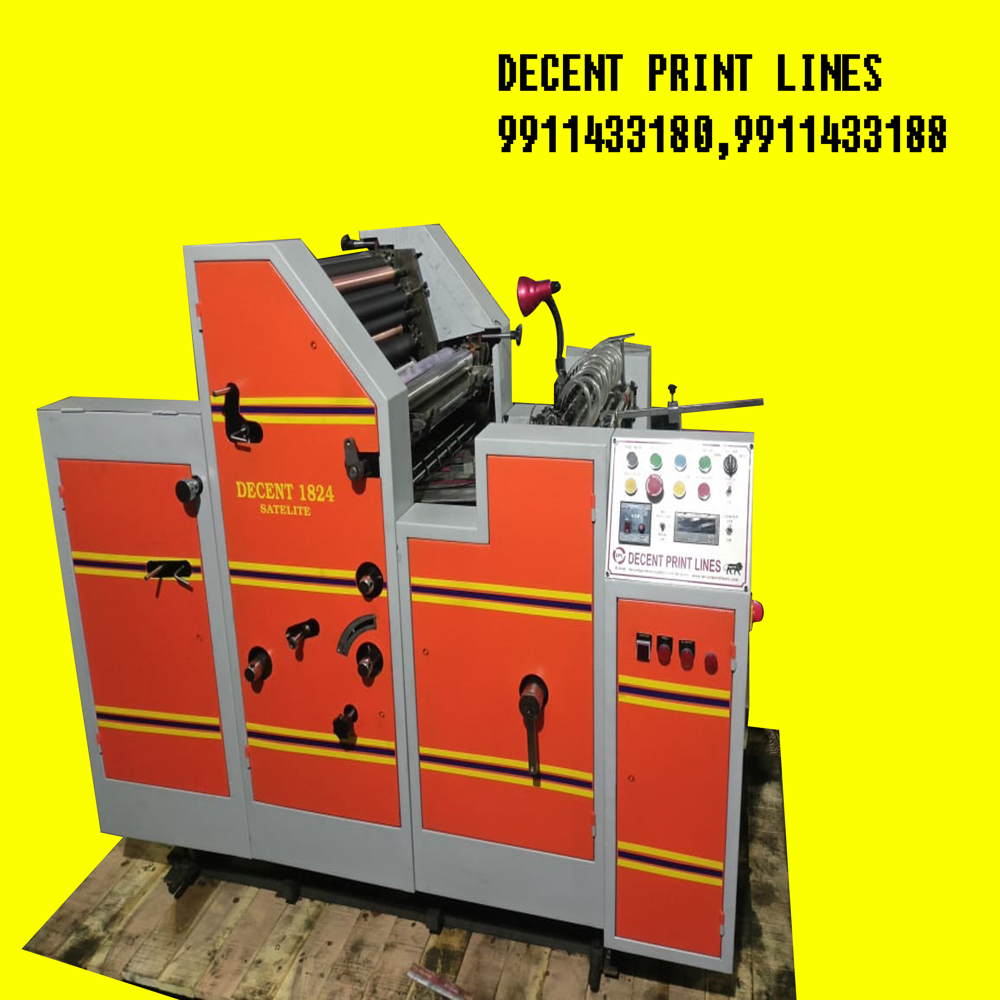

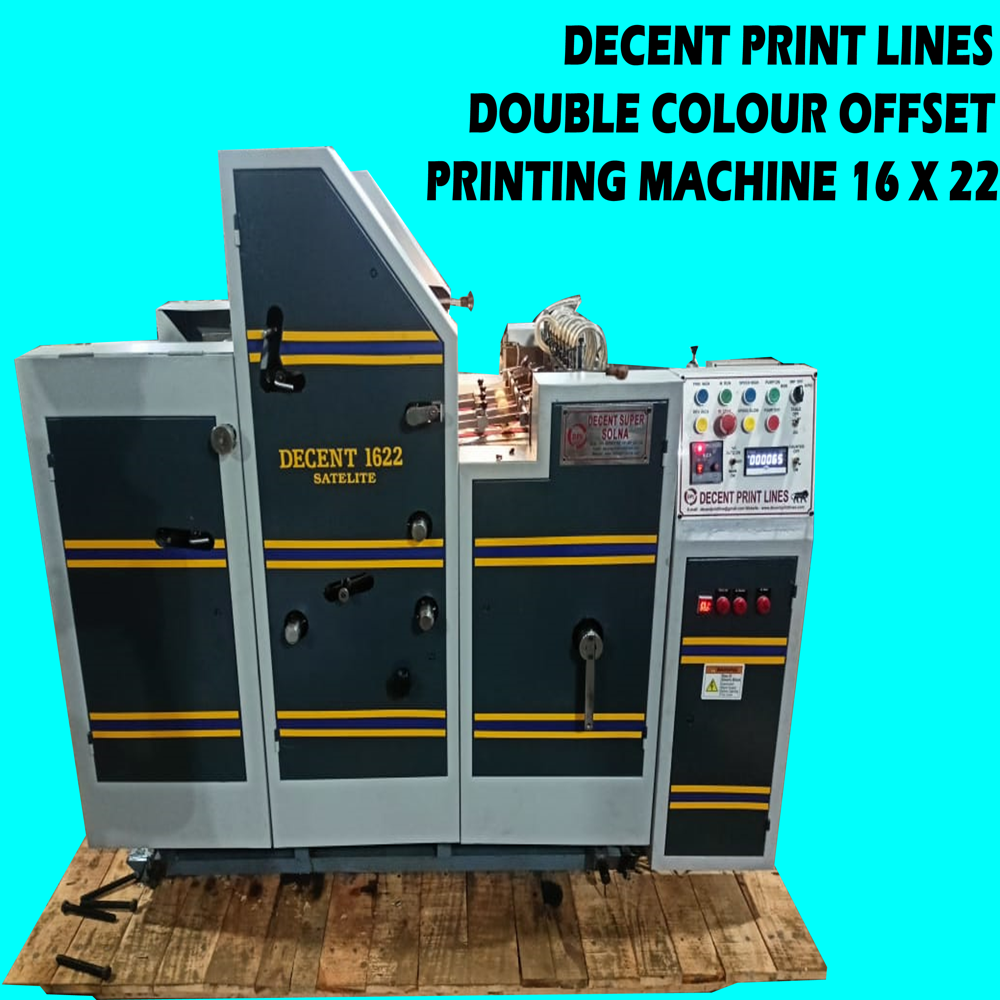

Two Color Non Woven Bag Printing Machine 16X22

Two Color Non Woven Bag Printing Machine 16X22 Specification

- Type

- Offset Printing Machine

- Material

- Non-Woven Fabric

- Computerized

- Yes

- Automatic Grade

- Automatic

- Power

- 220V/380V Volt (v)

- Size

- Standard/Custom

- Weight (kg)

- Approx. 1000 kg Kilograms (kg)

- Warranty

- 1 Year

Two Color Non Woven Bag Printing Machine 16X22 Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 4 Units Per Month

- Delivery Time

- 10 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

About Two Color Non Woven Bag Printing Machine 16X22

A double color non-woven bag printing machine is a specialized piece of equipment designed to print two distinct colors on non-woven bags in a single pass. These machines are commonly based on offset printing technology, though flexographic options also exist. They are highly sought after for producing professional-looking promotional and shopping bags with logos, branding, and basic designs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Non Woven Bag Printing Machine Category

Offset Carry Bag Printing Machine

Price 650000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Type : Bag Printing Machine

Material : MS

Computerized : No

Multi Color Offset Printing Machine With UV Dryer

Price 1450000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Type : Offset Color Printing Machine

Material : MS

Computerized : No

D-Cut Bag Printing Machine

Price 550000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Type : Flexographic

Material : Nonwoven fabric

Computerized : Yes

SUPER SOLNA MODAL PRINTING MACHINE

Price 750000.00 INR / Piece

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Type : PRINTING MACHINE

Material : Mild Steel

Computerized : No

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese