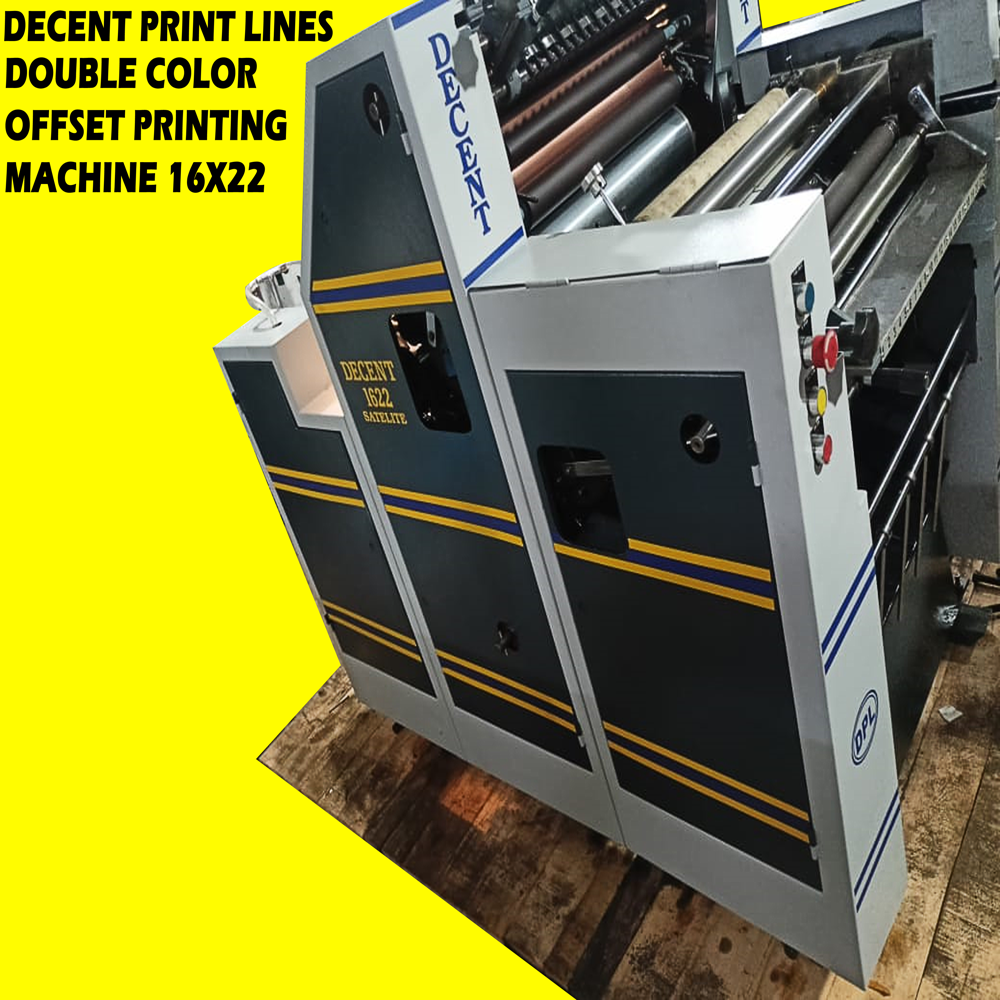

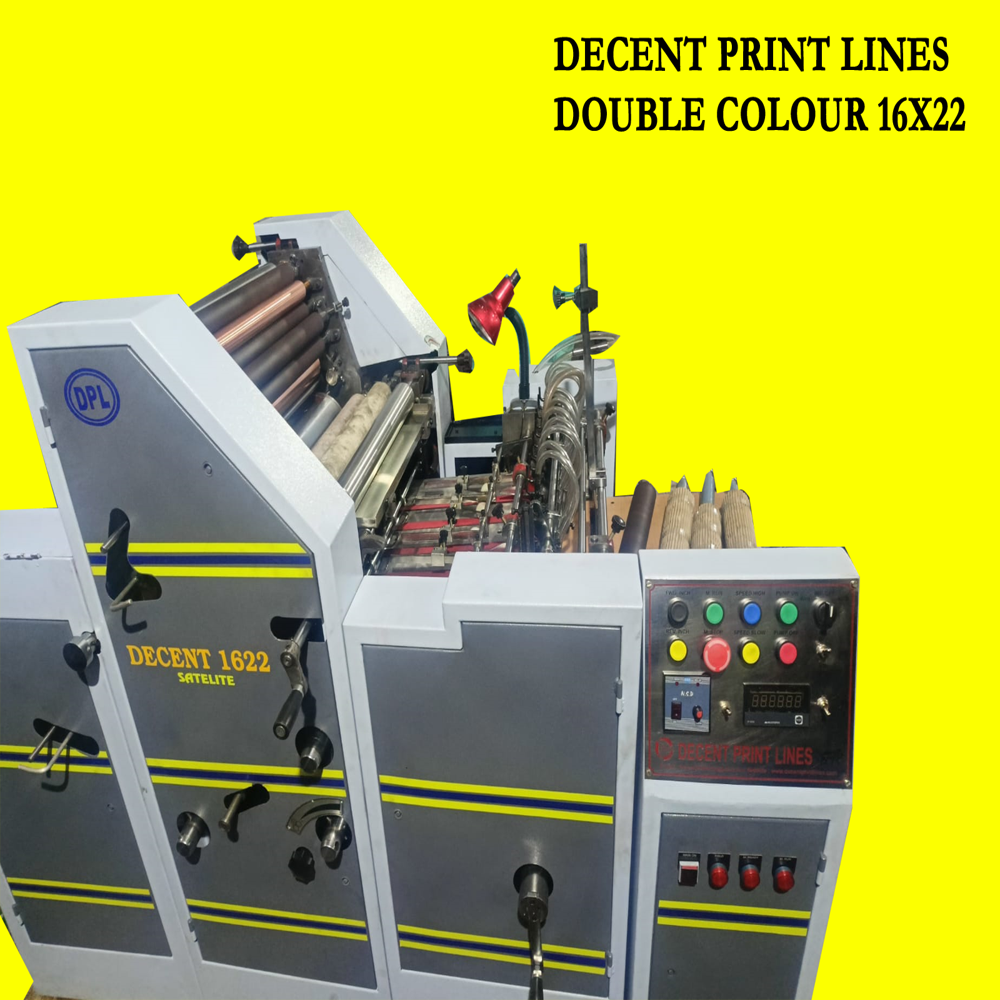

Offset Carry Bag Printing Machine

Offset Carry Bag Printing Machine Specification

- Type

- Bag Printing Machine

- Material

- MS

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Warranty

- 1 Year

Offset Carry Bag Printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- mumbai

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 12 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden box

- Main Export Market(s)

- Asia, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

- Certifications

- IEC certificate,Bank AD Code,Invoice,Packing List,etc.

About Offset Carry Bag Printing Machine

A double color non-woven bag printing machine is a specialized piece of equipment designed to print two distinct colors on non-woven bags in a single pass. These machines are commonly based on offset printing technology, though flexographic options also exist. They are highly sought after for producing professional-looking promotional and shopping bags with logos, branding, and basic designs.

Here's a detailed breakdown of specifications you'd typically find for a double color non-woven bag printing machine, drawing from examples available in the Indian market (like Decent Print Lines in Faridabad):

I. Core Specifications:

-

Number of Colors: 2 (Prints two distinct colors in one pass).

-

Printing Technology: Primarily Sheet-fed Offset. Some flexographic models are also available for specific applications. Many machines are "2-in-1" or "3-in-1," meaning they can print on non-woven bags, paper, and sometimes plastics.

-

Maximum and Minimum Bag/Sheet Size (Common Ranges):

-

Max Bag/Sheet Size:

-

Typically ranges from 406 x 560 mm (16" x 22") to 457 x 620 mm (18" x 24.5"). Some models may go slightly larger or smaller.

-

-

Max Printing Area:

-

Usually slightly smaller than the max sheet size, e.g., 375 x 550 mm to 440 x 605 mm.

-

-

Min Bag/Sheet Size:

-

Commonly around 125 x 180 mm or 180 x 260 mm.

-

-

-

Material Thickness Compatibility (GSM - grams per square meter):

-

Non-woven Bag Thickness: Typically 42 GSM to 150 GSM. Some robust machines might handle up to 300 GSM.

-

Paper Thickness (if dual-purpose): 30 GSM to 250 GSM, and in some cases, up to 300 GSM.

-

-

Printing Speed (Impressions Per Hour - IPH or Pieces Per Minute - PPM):

-

For Non-Woven Bags: 2000-3000 IPH (Impressions Per Hour) or around 40-120 pcs/min (Pieces Per Minute), depending on the automation level and specific machine design.

-

For Paper (if dual-purpose): Significantly higher, often 2000-8000 IPH.

-

-

Plate and Blanket Sizes:

-

Plate Size: Specific dimensions matching the printing area, e.g., 420 x 560 mm or 480 x 620 mm. Plate thickness is usually around 0.15mm to 0.28mm.

-

Blanket Size: Corresponding dimensions for the offset blanket, e.g., 460 x 560 x 1.9 mm or 515 x 620 x 1.9 mm.

-

II. Mechanical & System Specifications:

-

Ink Roller System:

-

Typically features 14 ink rollers per unit (for each color), with 3 form inking rollers for effective ink distribution and consistent print quality.

-

Some models might have 10 ink rollers with 2 form rollers per unit.

-

-

Water Roller System (Dampening):

-

Usually 5 water rollers per unit (for each color), with 2 form rollers to maintain the non-image area of the plate.

-

Dampening method: Often Mollention or similar.

-

-

Feeder System:

-

Automatic Feeder: Most modern double color machines come with an automatic feeding system, often a multi-sucker universal feeder or vacuum front feeder, for efficient and continuous material input.

-

Front Loading System: Simplifies material loading.

-

-

Delivery System:

-

Chain Delivery System with Receding Stacker: Ensures neatly collected printed bags or sheets.

-

Jogger System: Helps to collect and align bags/papers on delivery.

-

-

Cylinders:

-

Hard Chromium Faced Cylinders: For durability and precise printing.

-

Often involves two plate cylinders and a common blanket cylinder for transferring both colors to the bag.

-

-

Gears:

-

Hard & Ground Gears / Helical Gears: For smooth operation, accuracy, and longevity.

-

III. Electrical & Operational Specifications:

-

Power Requirements:

-

Voltage: Commonly 220V/50Hz (single phase) or 380V (three phase), depending on the machine's overall power consumption and specific model.

-

Power Consumption: Ranges from 1.1 kW to 3 kW (or 1.5 HP to 4 HP) for the main motor. Overall power might be higher if including drying systems and other features (e.g., 2.5 kW to 17 kW total power).

-

-

Automation Grade:

-

Most double color non-woven bag printing machines are Automatic or Semi-Automatic, offering features like automatic feeding, printing registration, and drying.

-

-

Control System:

-

Touch Screen Control Panel: For user-friendly operation, setting parameters, and monitoring.

-

Frequency Speed Control: For adjustable printing speed.

-

Computerized: Modern machines often have computerized controls for precision.

-

IV. Advanced Features & Benefits:

-

Perfect Registration: Crucial for accurate alignment of the two colors, ensuring high-quality prints. Achieved through features like pull-type side lay with micro adjustment and pneumatic impression.

-

Pneumatic Impression with Compressor: Uses air pressure for consistent and sharp impressions.

-

Automatic Ink Feed System / Automatic Ink Cleaning Device: Reduces manual effort and maintenance.

-

Centralized Oil Lubrication System: Ensures smooth operation and prolongs machine life.

-

Pre-set Copy Counter: For production tracking and managing print runs.

-

Double Sheet Detector: Prevents machine damage and material waste.

-

Anti-static System/Charger: To remove static electricity from non-woven bags, which can cause feeding and printing issues.

-

Exhaust Fan for Quick Drying: Especially important for faster production speeds.

-

Single Lever Operation: Simplifies the control of inking, dampening, and impression.

-

Short Changeover Time: Designed for quick setup between different print jobs.

-

Resistance to Moisture and Rust: Durable construction with features like hard chromium faced cylinders.

-

Compact Design: Optimized for space efficiency.

-

Ability to print on both sides in a single pass (for some models like "Two-Side" or "Satellite" models): This is a significant advantage, reducing production time.

V. Physical Specifications:

-

Machine Dimensions (L x W x H): Varies greatly by model, e.g., 1760 x 935 x 1340 mm up to 3500 x 1200 x 1500 mm.

-

Weight: Can range from 700 kg to 1500 kg or more, depending on the machine's size and features.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Woven Bag Printing Machine Category

Non Woven bag Printing Machines

Price 550000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Type : Printing Machine

Automatic Grade : Automatic

Material : cast iron

Two Color Non Woven Bag Printing Machine 16X22

Price 650000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Type : Offset Printing Machine

Automatic Grade : Automatic

Material : NonWoven Fabric

Single Color Non woven Bag Printing Machine

Price 450000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Type : PRINTING MACHINE

Automatic Grade : SemiAutomatic

Material : Mild Steel

Non Woven Printing Machine

Price 550000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Type : PRINTING MACHINE

Automatic Grade : SemiAutomatic

Material : Mild Steel

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese