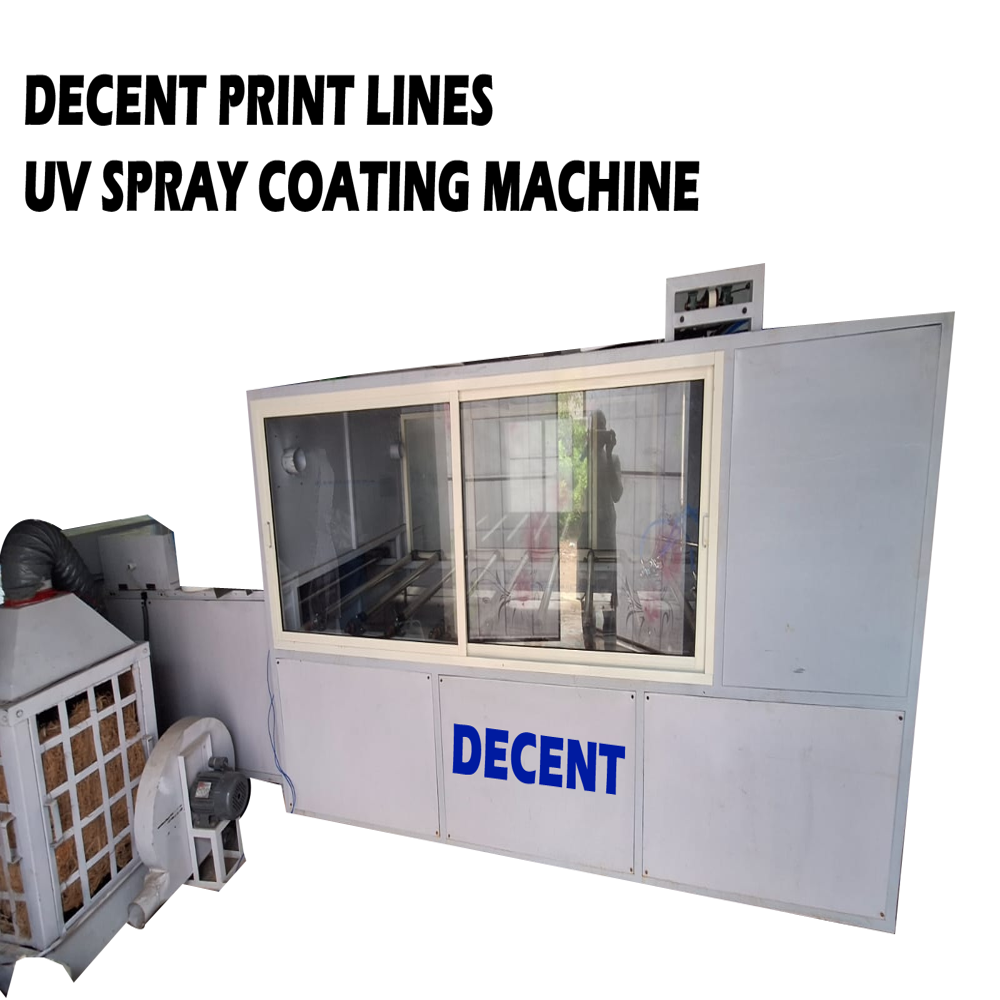

Automatic UV Spray Coating Machine

Automatic UV Spray Coating Machine Specification

- Type

- Uv Coating Machine

- Material

- MS

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Human Machine Interface

- Warranty

- 1 Year

Automatic UV Spray Coating Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque, Cash in Advance (CID)

- Delivery Time

- 45 Days

- Packaging Details

- Bubbles poly bag and wooden cartoon

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India, Delhi

About Automatic UV Spray Coating Machine

A UV Ultraviolet spray coating machine is a specialized industrial equipment used to apply a liquid UVcurable coating onto various substrates using a spray application method followed by instant curing with UV light Unlike roller coaters that are ideal for flat sheets spray coating machines are particularly effective for objects with irregular shapes 3D contours or where a very even thin and precise layer is required over complex geometries

These machines are widely used in sectors like furniture wood MDF automotive parts plastics electronics and even for specialized printing applications where roller coating isnt feasible In Faridabad youll find manufacturers like Decent Print Lines Simsan Enterprises True Colors Solutions and SK Ensure Machinery Private Limited among others that offer UV spray coating and curing solutions

Key Specifications of UV Spray Coating Machines

Coating Method

Automated Spray Guns The core of the machine typically featuring multiple automatic spray guns eg 2 4 or more to ensure even coverage Some systems may also include manual guns for touchups or specific areas

Robotic Spraying Advanced For highly complex or variable shapes robotic arms can be integrated for precise and repeatable coating paths

Electrostatic Spraying Optional Can be used for improved transfer efficiency and wraparound coating especially on conductive substrates

Substrate Compatibility Application

WoodMDF Furniture panels cabinet doors flooring decorative moldings

Plastics Automotive interiorexterior parts electronic housings consumer goods PVC profiles mobile phone cases

Metal Small components decorative items sometimes larger sheets

Glass Bottles decorative glass

Ceramics Tiles sanitaryware

Specific industries Automotive furniture electronics construction materials WPC PVC sheets consumer goods

Maximum and Minimum Workpiece Dimensions

This defines the size of the objects the machine can handle

Maximum Coating Width From 24 inches 600mm to 48 inches 1200mm or more depending on the machines scale and number of spray guns

MaximumMinimum LengthHeight Crucial for 3D objects Specifications might include the maximum height of the product or the working envelope for robotic systems

Example Min Work Size 4 feet Max Work Size 7 feet for larger industrial systems

Conveyor System

Type Often a mesh belt conveyor chain conveyor or overhead conveyor system depending on the objects shape and weight

Speed Adjustable measured in meters per minute mpm or pieces per minute ppm Highspeed conveyors are common for continuous production lines eg 80009000 SHP Sheets Per Hour or pieces per hour for fully automatic lines

Material Often Stainless Steel SS rollers or heatresistant belts

Auto SS Roller Feeding Station Common for flat panels

UV Curing Section

Number of UV Lamps Typically 1 to 4 UV lamps depending on the required curing intensity and speed

Lamp PowerIntensity Measured in Watts per inch Winch or Kilowatts kW Higher power lamps ensure faster and more complete curing eg 200500 Winch

Lamp Cooling System Forced air cooling blowers or water cooling systems to manage heat and extend lamp life

UV Ray Shielding Safety measures to prevent UV exposure to operators

Automatic Lamp ONOFF Lamps activate only when material is present saving energy and extending lamp life

Spray BoothEnclosure

Material Stainless steel SS or CR material for durability and easy cleaning

Exhaust System Highpower suction blowers and filtration systems to remove overspray solvent vapors if any and ensure a clean working environment Essential for safety and environmental compliance

Chemical Collector Tray For efficient reuse of excess UV coating material minimizing waste

Booth Controller Often PLC Programmable Logic Controller based for precise control of spray patterns conveyor speed and environmental conditions within the booth

Coating Circulation and Supply System

Automatic Supply System For continuous feeding of UV coating material to the spray guns

Filtering System To ensure clean coating material and prevent nozzle clogging

Temperature Control Maintaining optimal coating viscosity

Chemical Reuse System Collects overspray for filtration and reuse reducing material consumption

Power Requirements

Voltage Usually 3phase eg 340V 380V 415V 440V for industrial power

Total Power Consumption kW Can range significantly from 15 kW to 60 kW or more depending on the length of the line number of spray guns and UV lamp power

Automation Grade

Fully Automatic Most UV spray coating machines are designed to be fully automatic integrating feeding spraying curing and often unloading This ensures high throughput and consistent quality with minimal human intervention

5Axis Automation For highly complex 3D objects advanced machines might feature 5axis robotic arms for ultimate precision and flexibility in spray patterns

Dimensions and Weight

These machines can be quite large especially with integrated conveyors and multiple spraycuring zones

Machine Length Can range from 30 feet approx 9 meters to 60 feet approx 18 meters or even more

Machine WidthHeight Also substantial requiring significant factory floor space

IV Advantages of UV Spray Coating

Versatility Ideal for objects with complex geometries curves and angles that are difficult to coat uniformly with rollers

Uniform Coverage Spray guns can provide a very even and thin layer of coating

High GlossMatte Finishes Can achieve various finishes from high gloss to smooth matte

Enhanced Durability UV coatings offer excellent scratch abrasion chemical and moisture resistance

Instant Curing UV light cures the coating almost instantly allowing for immediate handling stacking and further processing drastically reducing production time

Environmentally Friendly UV coatings are typically 100 solid or have very low VOCs Volatile Organic Compounds making them more ecofriendly compared to solventbased coatings

CostEffective Long Term Reduced drying time less material waste with reclaim systems and enhanced product durability contribute to overall cost savings

When considering a UV spray coating machine its crucial to provide manufacturers with detailed information about the specific products you intend to coat their dimensions desired finish and production volume Companies in Faridabad and surrounding regions can then offer tailored solutions

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

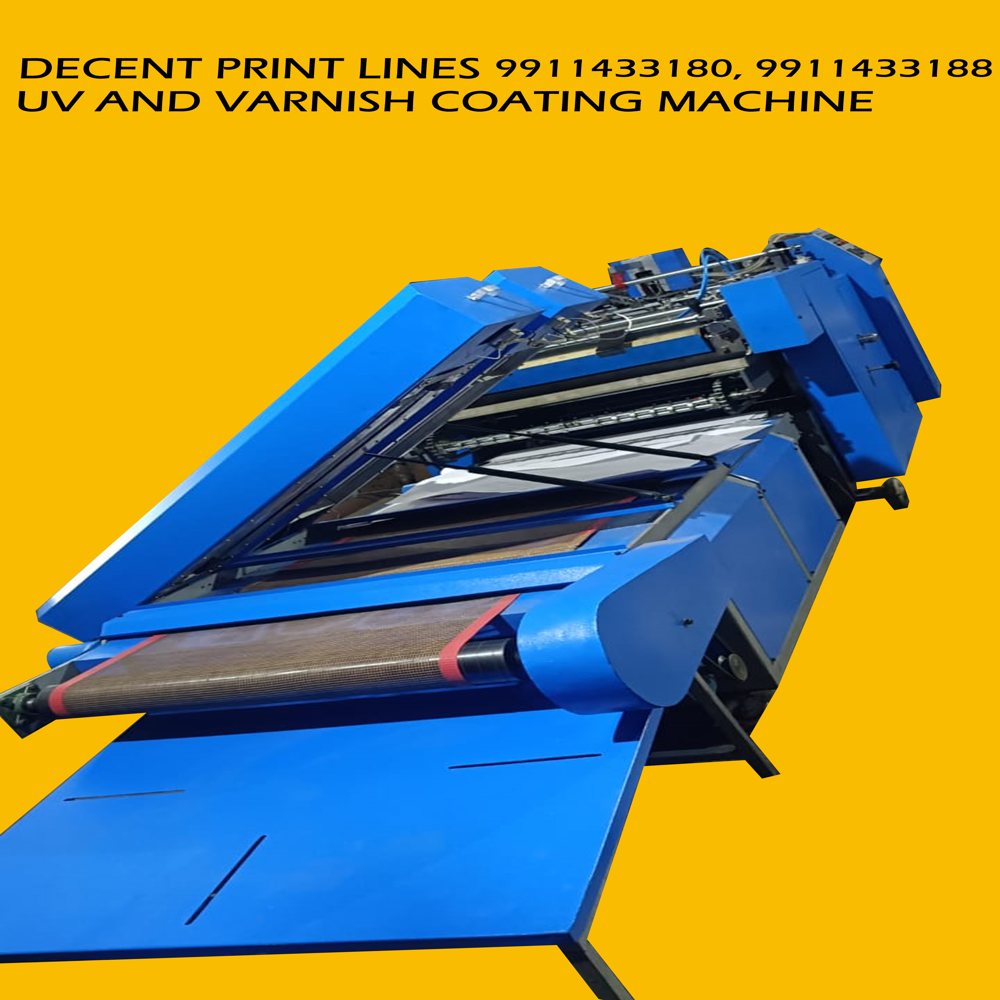

More Products in UV Coating machinery Category

UV and Aqua Varnish Coating Machine Fully Automatic

Price 850000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Warranty : 1 year

Material : Mild Steel

Type : Varnish Coating Machine

UV Coating and UV Curing Machine

Price 550000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Warranty : 1 Year

Material : Metal

Type : UV Coating and UV Curing Machine

Aqua Varnish Coating Machine Manual

Price 500000.0 INR / Piece

Minimum Order Quantity : 1 Unit

Computerized : No

Warranty : 1 Year

Material : MS

Type : Varnish Coating Machine

Fully Automatic UV Coating Machine

Price 1250000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Warranty : Manufacturers Warranty

Material : Metal and Plastic

Type : UV Coating Machine

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese