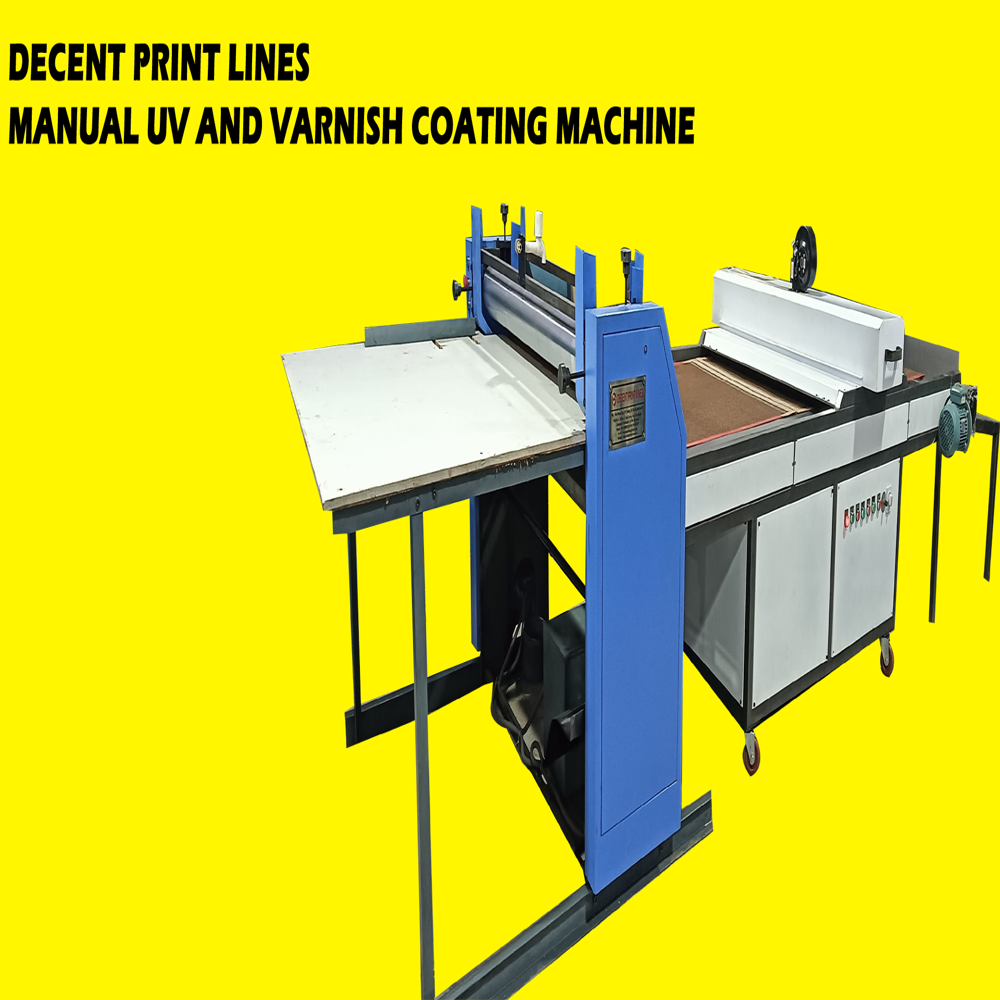

A UV Ultraviolet coating machine is a crucial piece of equipment in the printing and finishing industry It applies a liquidbased often glossy clear coating to printed materials which is then instantly cured hardened by exposure to ultraviolet light This process enhances the aesthetic appeal durability and protection of the printed product

Heres a comprehensive breakdown of UV coating machine specifications

I Types of UV Coating Machines

Before diving into specifications its helpful to understand the different types

FullFlood UV Coaters Apply UV coating to the entire surface of the material

Spot UV Coaters Apply UV coating to specific areas of a print creating a contrasting matte and glossy effect often using a printing plate similar to offset

DripOff UV Coaters A specialized type of spot UV that creates a textured drip or orange peel effect by applying a matte varnish followed by a highgloss UV coating

Roller Coaters The most common type where the coating is applied via a series of rollers

Spray Coaters For irregular shapes or specific industrial applications

Tabletop UV Coaters Compact models for smallscale operations or testing

Online vs Offline

Online Integrated directly with a printing press applying the coating immediately after printing

Offline A standalone machine where printed sheets are fed after the printing process

II Key Specifications of UV Coating Machines

Coating Method

Roller Coating The most prevalent for sheetfed applications

Spray Coating For irregular surfaces or specialized industrial use

Maximum and Minimum Sheet Size

This defines the dimensions of the paper board or other substrate the machine can coat Common ranges include

Max Sheet Size From 386 x 515 mm 15 x 20 for smaller machines up to 730 x 1040 mm 28 x 40 or even larger for industrial models

Min Sheet Size Can be as small as 125 x 180 mm or 210 x 250 mm

Material Thickness Compatibility GSM or mm

PaperBoard Typically ranges from 60 GSM to 450 GSM Highend machines might handle up to 600800 GSM board

Other Substrates Some machines are designed for wider thickness ranges to coat plastic sheets PVC wood metal glass etc handling thicknesses from 1 mm up to 60 mm

Coating Speed Impressions Per Hour IPH or meters per minute

Varies significantly based on automation level machine size and coating type

Automatic Machines Can range from 2000 to 8000 IPH

SemiAutomaticManual Lower speeds often 10003000 IPH or 1540 meters per minute for conveyortype systems

UV Lamp Specifications

Number of Lamps Typically 1 to 3 UV lamps Some larger systems may have more

Lamp IntensityPower Measured in Watts per inch Winch or Kilowatts kW Common intensities are 200500 Winch

Example 400 Wattinch equivalent to 100 kW to 208 kW for wider machines

Lamp Life Important for maintenance planning

Cooling System Essential to dissipate heat generated by UV lamps eg blowers water cooling systems

UV Ray Leaking Prevention Device Safety feature

Automatic Lamp ONOFF Lamps turn off if the conveyor stops or material flow is interrupted

IR Infrared CuringDrying System Optional but common

Used for aqueous waterbased coatings or for predrying before UV coating

Number of IR lamps and their power eg 24 x 1KW lamps

Automation Grade

Manual Operator feeds sheets one by one

SemiAutomatic Features an automatic feeder but delivery might be manual

Automatic Includes automatic feeding coating curing and stackingdelivery systems

Feeding System

Automatic Feeder Often a vacuum suction feeder for smooth continuous sheet feeding

Pile Height Feeder The maximum stack height the feeder can handle eg 350 mm 800 mm

Delivery System

Chain Delivery with Receding Stacker For neat stacking of coated sheets

Automatic Down Pile Delivery Automatically lowers the stack

Vacuumbased Absorption Paper Delivery Ensures stable paper movement throughout the coating process

Coating Control

Adjustable Coating Thickness Allows for varying gloss levels and protection eg 38 GSM coating thickness

Roller System Precision rollers eg rubber metering impression rollers for uniform coating application

Speed Differential Oil Delivery System For optimized coating

Grid Ceramic Roller Anilox Roller For precise and consistent coating application especially for spot UV

Power Requirements

Voltage Usually 220V380V440V threephase is common for larger machines

Total Power Consumption kW or HP Can range from 2 kW for smaller models to 55 kW or more for large fully automatic systems

Machine Dimensions and Weight

Crucial for factory layout and installation

Dimensions L x W x H and weight vary widely based on size and features eg Weight 700 kg to 8500 kg

III Additional Features and Considerations

UserFriendly Interface Touch screen control panels for easy operation and monitoring

Safety Features Emergency stop buttons UV ray leaking prevention automatic shutoff if covers are opened

Precise Registration for Spot UV Features like swingingdownward front lay or rotating side lay for accurate sheet positioning

AntiScratchAntiStatic Devices To prevent marks and ensure smooth material handling

Automatic Roller Cleaning System Reduces maintenance time

Chemical Circulation System For efficient management of UV varnish

Durable Construction Stainless steel and mild steel components for longevity

Versatility Ability to handle various types of UV and aqueous coatings gloss matte textured

Applications

Printing Industry Brochures business cards book covers posters calendars magazines

Packaging Industry Carton boxes product packaging labels

Other Industries Wood panels furniture components plastic sheets metal plates glass PVC profiles medical devices photography

When purchasing a UV coating machine its vital to assess your production volume the types of materials youll be coating desired finish quality full spot dripoff and budget Manufacturers in Faridabad and across India like Autoprint Decent Print Lines P3 Machinery SK Ensure Machinery Unison Machinery etc offer a wide range of options to suit different business needs

Sources

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese