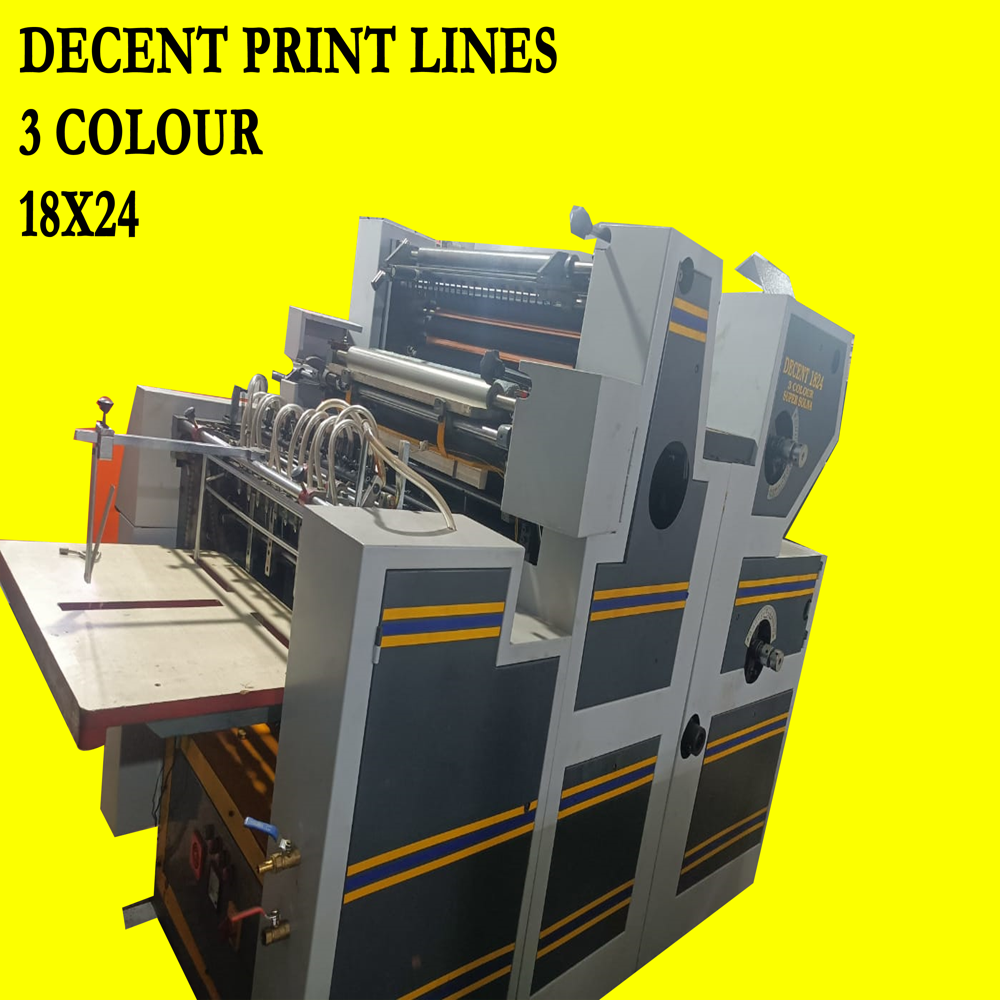

Three Color Non Woven Bag printing Machine

Three Color Non Woven Bag printing Machine Specification

- Type

- Non Woven Sheet Printing Machine

- Material

- Non-Woven Fabric

- Capacity

- 6000 Pcs/hr

- Printing Speed

- 6000 PPM

- Computerized

- No

- Automatic Grade

- Automatic

- Plate Type

- Other

- Print Direction

- Bi-Directional

- Ink Type

- Other

- Color Management

- Other

- Control System

- Human Machine Interface

- Working Temperature

- 10 C - 50 C Celsius (oC)

- Power

- 7 Horsepower (HP)

- Size

- Medium

- Width

- 5 Foot (ft)

- Weight (kg)

- 2500 Kilograms (kg)

- Dimension (L*W*H)

- 8 Foot (ft)

- Warranty

- 1 year

Three Color Non Woven Bag printing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- mumbai

- Payment Terms

- Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 15 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- wooden box

- Main Export Market(s)

- Asia, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

About Three Color Non Woven Bag printing Machine

Non-woven bag printing machines are essential equipment for businesses looking to produce custom-designed non-woven bags. These machines come in various types, each with its own set of specifications and capabilities. Here's a breakdown of common specifications and factors to consider:

Key Specifications of Non-Woven Bag Printing Machines:

-

Printing Technology:

-

Offset Printing: Known for high-quality, detailed prints with accurate color reproduction, suitable for large print runs. Many non-woven bag printing machines are modified offset presses.

-

Flexographic (Flexo) Printing: Ideal for high-volume orders, offering excellent speed and cost-effectiveness. Uses flexible relief plates.

-

Screen Printing: Provides vibrant colors and a unique textured finish, suitable for smaller runs and specialty designs. Involves pushing ink through a mesh screen.

-

Digital Printing: Uses computer-controlled equipment to print images directly onto bags, offering versatility for intricate designs and variable data printing.

-

Heat Transfer Printing: Involves transferring an image from a sheet to the bag using heat and pressure. Offers full-color printing and durability.

-

-

Number of Colors:

-

Single Color: For basic logos or text.

-

Two Color: Allows for more complex designs with two distinct colors.

-

Multi-color (e.g., 3-color, 4-color, up to 8 colors): For elaborate designs, gradients, and photographic quality prints.

-

-

Maximum and Minimum Bag/Sheet Size:

-

This specifies the dimensions of the non-woven bags or sheets the machine can accommodate. Common ranges vary widely, for example:

-

Max Bag Length: 200-800mm

-

Max Bag Width: 100-800mm

-

Max Printing Area: Varies based on the machine model, e.g., 345x450mm to 605x420mm.

-

Minimum Bag Size: Can be as small as 125x180mm.

-

-

-

Material Thickness Compatibility (GSM - grams per square meter):

-

Bag Thickness: Typically ranges from 30 GSM to 150 GSM or even up to 300 GSM, depending on the machine.

-

Paper Thickness (if applicable): Many non-woven bag printing machines can also print on paper, with a thickness range often from 30 GSM to 250-300 GSM.

-

-

Printing Speed (Impressions Per Hour - IPH or meters per minute):

-

Varies significantly based on automation level and printing technology.

-

For bags, speeds can range from 20-120 pcs/min (for bag making machines with printing) or 2000-3000 IPH for dedicated printing machines.

-

For paper (if dual-purpose), speeds can be much higher, e.g., 2000-8000 IPH.

-

-

Automation Grade:

-

Manual: Requires significant operator intervention.

-

Semi-Automatic: Some processes are automated, while others require manual feeding or handling.

-

Automatic: Features like automatic feeding, printing registration, and drying systems for high efficiency and reduced labor.

-

-

Power Requirements:

-

Voltage: Often 220V/50Hz or 380V (three-phase).

-

Power Consumption (kW or HP): Varies from 1.1 kW to 18 kW or more, depending on the machine's size and capabilities.

-

-

Machine Dimensions and Weight:

-

Important for planning factory space and installation.

-

Weight can range from a few hundred kilograms (e.g., 150 kg for semi-automatic) to several tons (e.g., 2000 kg - 4000 kg for fully automatic).

-

-

Ink System:

-

Ink Rollers: Number of ink rollers (e.g., 10, 14, 16) and form rollers (e.g., 2, 3) for even ink distribution.

-

Water Rollers: Number of water rollers (e.g., 4, 5) for dampening (especially in offset printing).

-

Ink Type: Water-based inks are commonly used for non-woven bags due to environmental considerations. UV inks may be used for digital printing.

-

-

Additional Features:

-

Automatic Feeding System: Ensures continuous flow of bags.

-

Automatic Printing Registration: Guarantees precise alignment of colors.

-

Automatic Drying System: Prevents smudging (e.g., exhaust fans, heating systems).

-

Pneumatic Impression: Uses air pressure for consistent printing.

-

Centralized Oil Lubrication System: For smooth operation and reduced maintenance.

-

Pre-set Copy Counter: For production tracking.

-

Double Sheet Detector: Prevents machine damage and material waste.

-

Anti-static Charger: To remove static from the material.

-

Touch Screen Control Panel: For user-friendly operation.

-

Safety Features: Emergency stop buttons, safety guards.

-

Skip Feed Function: To control ink density.

-

2-in-1 Capability: Some machines can print on both non-woven bags and paper sheets.

-

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Non Woven Bag Printing Machine Category

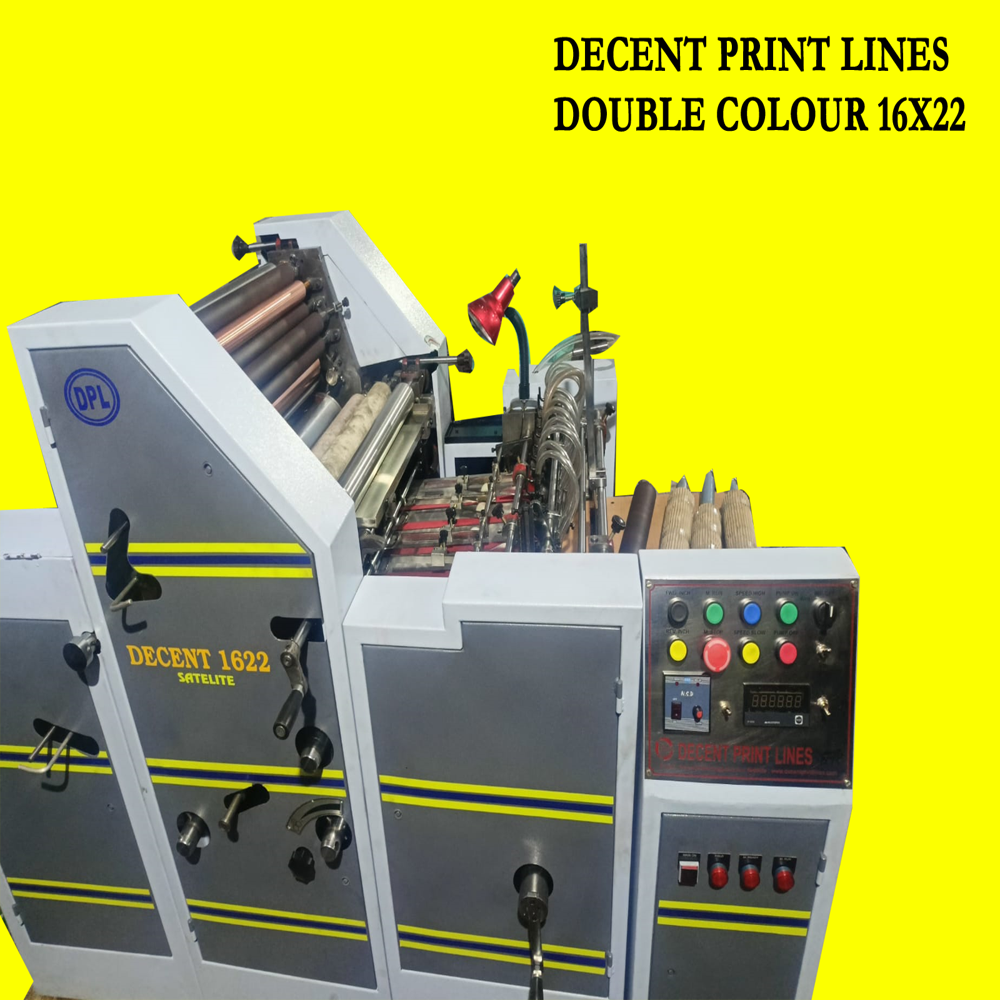

Double color Fabric Bag Printing Machine

Price 650000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Type : Offset Printing Machine

Computerized : No

Material : Fabric Bags

Non Woven bag Printing Machines

Price 550000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Type : Printing Machine

Computerized : No

Material : cast iron

Multi Color Offset Printing Machine With UV Dryer

Price 1450000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Type : Offset Color Printing Machine

Computerized : No

Material : MS

Non Woven Printing Machine

Price 550000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Type : PRINTING MACHINE

Computerized : Yes

Material : Mild Steel

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese